Quality is a term used in industry to measure the standard of products, it indicates the level of technical requirements of the finished product.

The quality of forgings is evaluated according to technical conditions or related standards, forgings must not only meet the requirements of the end user specified in the parts, but also meet the requirements of the intermediate links.

In actual production, according to the various degrees of forging design, divide the forgings into qualified parts, repaired parts, defective parts and waster.

The review of forging surface defects is a very complex and extensive work, can be commented according to the reason of the defect, can be commented on the responsibility of the defect, it can also be described by the location of the defect, therefore it is necessary to classify it.

The review of forging surface defects is a very complex and extensive work, can be commented according to the reason of the defect, can be commented on the responsibility of the defect, it can also be described by the location of the defect, therefore it is necessary to classify it.

1.According to the defective process or quality defect produced in the production process, quality defect produced in the forging process and quality defect produced in the heat treatment process, etc.

2.Defects caused by raw materials. (1) Defects such as cracks, cracks, shrinkage holes, looseness, impurities, segregation, scars, bubbles, slag inclusions, blisters, folds, scratches, non-metallic inclusions, white spots, etc. (2) Defects such as longitudinal or transverse cracks and interlayers caused by raw material defects during forging. (3) Problems with the chemical composition of raw materials.

3.Defects caused by blanking are: Rough and uneven end faces, inclined end faces and insufficient length, end cracks, end burrs and interlayers, etc.

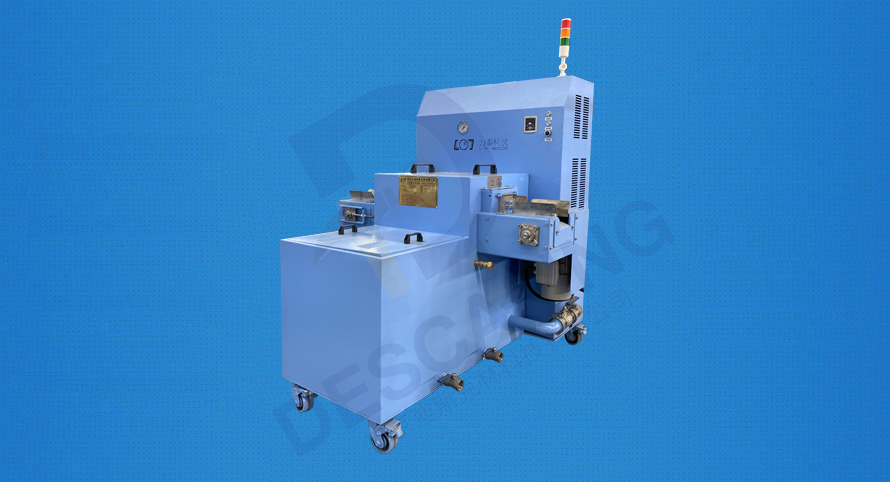

If you want to know more about forging surface defects, welcome to consult Nanjing Descaling Technology Co.,Ltd.:18952058568