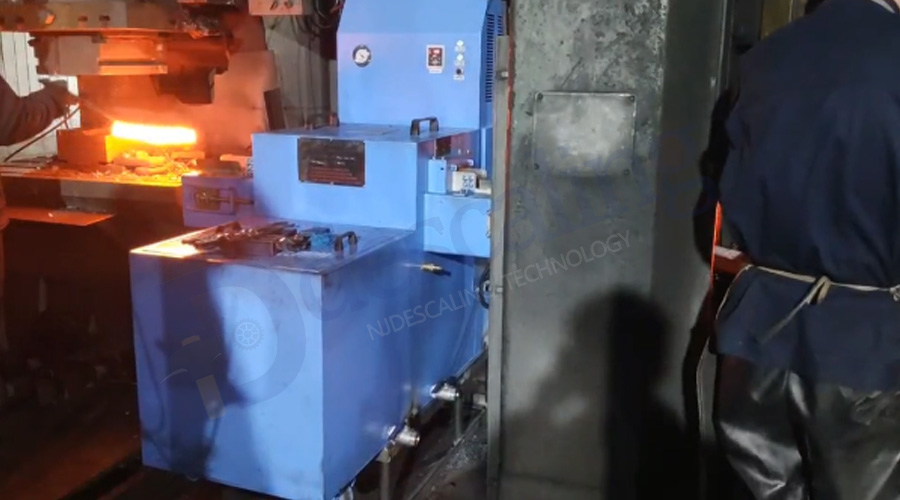

There are many types of forging products that need to be descaled in the forging plant. Manual descaling process cannot increase the output. The forging descaler automation equipment has gradually become the main forging and forming equipment in Chinese forging industry. The forging descaling automation equipment realizes better forging surface treatment, and requires low labor costs. It can produce more high-quality precision forgings for enterprises with less labor within a specified time, reducing labor and enterprise costs.

Forging automation equipment adopts various high-precision detection, adjustment, automatic data recording, and advanced precision production technology, which can maintain the accuracy of products during the production process. Compared with the old forging process, the working cycle of forging automation equipment is more strict, which can realize the rapid forging delivery, reduce the loss of raw materials, improve the production efficiency. For example,in the forging process of using the hot forging descaling machine, the automatic cleaning filter of the equipment can finely filter the inlet water of the main pump and control the water pressure of the inlet water. The filter adopts automatic backwashing method, which reduces the labor intensity of operators.

Ultra-high pressure water descaling equipment has been widely used in hot rolling forging production process and has become the mainstream of today's popular forging surface reatment methods. There are many cases of forging descaler machines on the Chinese market,and the feedback is very good.