Most of the customers who have inquired will mention whether the use of the forge scale descaling machine can eliminate the need for shot blasting. Today, We will give you a detailed analysis of the difference between the forging descaling machine and the shot blasting machine.

The oxide scale dephosphorization machine is used in hot forging, using the principle of high pressure water , carbon steel is oxidized at high temperature, and a dense layer of iron oxide scale (oxide skin) is formed on its surface. If this layer of iron oxide cannot be removed before rolling or forging process, it will be pressed into the surface of the strip by the roll during the rolling process, affecting its surface quality. The residual iron oxide scale will also accelerate the wear of the rolls and reduce the service life of the rolls or forging die. For example, when the strip needs to be pickled, the residual iron oxide scale will increase the difficulty of pickling and increase the acid consumption. Therefore, the scale on the forging surface must be removed before the billet is rolled. Therefore, it is recommended to use forging descaler machine before the round bar is heated and forged, or if there is a hot billet, it can be used after the billet is made. If possible it is necessary to add descaling equipment into these two processes, and the quality of the product will be better improved. The scale removed is produced by the induction forging furnace machine, which is very damaging to the product and to the forging die, so it is very necessary to add an oxide scale descaling machine.

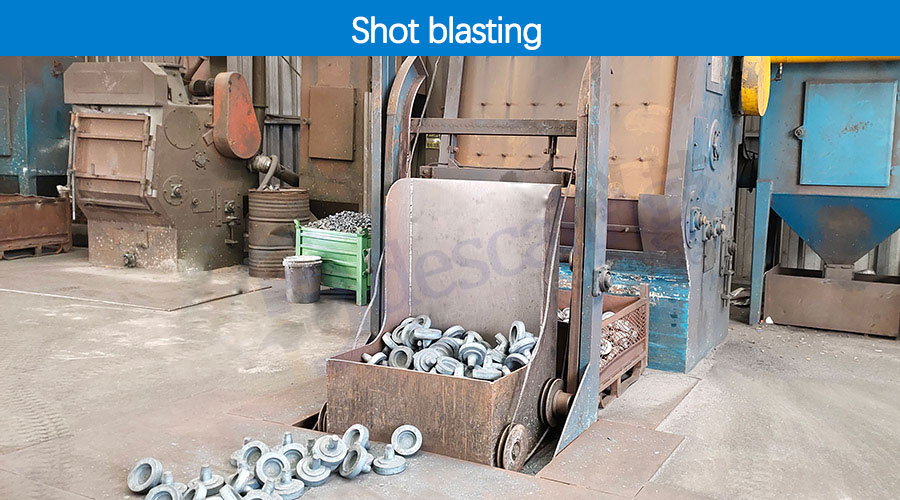

The principle of shot blasting is to use a motor to drive the impeller body to rotate (directly drive or drive with a V-belt), and rely on the action of centrifugal force to make projectiles with a diameter of about 0.2 to 3.0 (cast steel shot, steel wire cut shot, stainless steel shot, etc.) type) to the surface of the workpiece to make the surface of the workpiece reach a certain roughness, make the workpiece beautiful, or change the welding tensile stress of the workpiece to compressive stress to improve the service life of the workpiece. It is carried out under the condition of cooling down after the product is forged.

Therefore, to sum up, the forging scale descaling machine and the shot blasting machine are used in different forging processes, without conflict with each other, and the effects are mutually additive. If the descaler machine and the shot blasting machine can be used at the same forging production line, the problem of oxide scale is reduced to minimum, which is of great benefit to the improvement of the surface quality of forgings.

The forging iron scale removal machine made by Descaling Technology in China has been exported to many countries such as India and Indonesia, if you need more information please feel free to comntact us or visit our homepage.