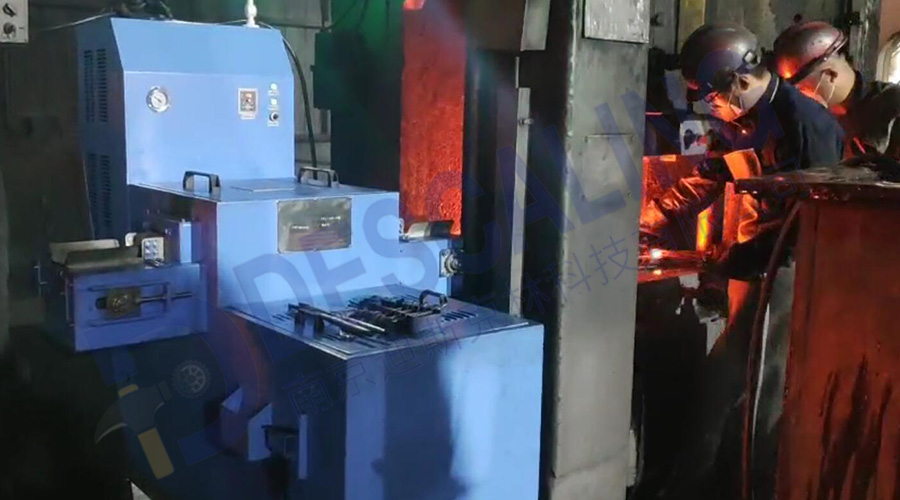

The forged oxide scale cleaning machine of Nanjing Descaling Technology uses the principle of high-pressure water descaling. In fact, the principle of high-pressure water descaling has been applied very early in the forging industry, and it is an ultra-high pressure technology, and the equipment cost is particularly high. The second is the manual hand-held high-pressure water gun to remove the oxide scale. The pump life is short, especially in winter. Our company invented the forging oxide scale cleaning machine in response to the actual needs of the majority of forging factory friends. It has passed the test of the market for five years and has obtained 6 national utility and appearance double patents. It professionally removes and collects forged oxide scale and helps companies solve oxidation. Problems such as defects caused by the leather. At present, the appearance of the equipment on the market comes from the appearance patent structure of our company. Our company has professional R&D personnel who constantly forge ahead to improve the scale cleaning machine and never cut corners.

The forging process generally consists of the following processes, namely blanking, heating, forming, cooling after forging, pickling and heat treatment after forging. If the forging process is improper, a series of surface defects of the forging may occur. For example, if the heating temperature is too high and the heating time is too long, it will cause defects such as decarburization, overheating, and over burning.

For blanks with large cross-sectional dimensions, poor thermal conductivity, and low plasticity, if the heating speed is too fast and the holding time is too short, the temperature distribution tends to be uneven, causing thermal stress and cracking of the blank. The forging forming process includes the deformation method, the degree of deformation, the deformation temperature, the deformation speed, the stress state, the mold and the lubrication conditions, etc. If the forming process is improper, it may cause coarse grains, uneven grains, various cracks, etc. Folding, cold current, eddy current, as-cast structure residue, etc. During the cooling process after forging, if the process is improper, it may cause cooling cracks, white spots, network carbides, etc.

Do these phenomena make you feel more terrible? Every step of the forging process should not be ignored. The serious surface defects of the forgings directly cause the waste, and the processing is also time-consuming and labor-intensive. As a forging factory that can be trusted by customers, we must always keep in mind the safety of personnel first and the key principles of product quality. Under appropriate circumstances, quality is more important than quantity. Descaling machine from Descaling Technology is used to deal with the oxidation of the forging surface during the forging process. To improve the forging process control and effectively improve the surface defects of forgings and achieve high production efficiency of forgings.