Auto Parts 4.3KW Regular Descaling Machine is applicable to the oxide scale cleaning of small size auto parts forgings, such as car gears, and it can clean the scale of 15-80mm diameter round bars after heating in induction furnace.

Item NO.:

DSKL-S1Payment:

50%DOWN PAYMENT,50% BEFORE SHIPPINGPrice:

$5000/setProduct Origin:

CHINAColor:

BLACKGoods stock:

100Product weight:

400 kgShipping Port:

QINGDAOLead Time:

1 MONTH

|

Auto Parts 4.3KW Regular Descaling Machine Auto Parts Regular Forging Descaling Machine can effectively clean the diameter of forgings round bars from15-80mm, and it can clean the oxide scale of all kinds of auto parts forgings, such as auto gears, connecting rods, crankshafts, etc. We could also customize the equipment according to different requirements. This descaling equipment could effectively clean the oxide scale produced by the induction furnace. |

|

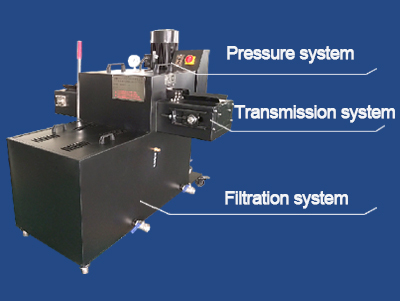

The descaling machine from Descaling technology, the main body of the equipment is composed of a pressure system, a transmission system and a filtration system. The three systems jointly use the principle of high-pressure water descaling to complete the cleaning process of the forging scale.

|

|

The high-pressure water descaling system is adopted, and the high-pressure water generated by the high-pressure water pump enters the descaling nozzle and is sprayed on the surface of the forging (or intermediate billet). The oxide scale has undergone the process of being cut, rapidly cooled and contracted, peeled from the base material, and washed away from the surface of the forging, thereby removing the oxide scale.

|

|

|

The descaling machine is equipped with two water tanks. The water tank has a built-in filter screen and a net basket to form the filter system of the equipment to prevent oxide scale from entering the water pump and affect the service life of the equipment. At the same time, it is equipped with a magnetic shovel to clean the oxide scale in the water tank.

|

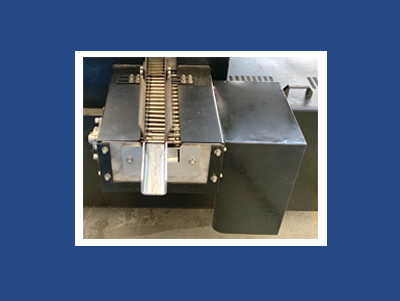

| The frequency conversion motor and the chain constitute the transmission system, which is responsible for transporting the forgings for the cleaning process. The transmission speed of the chain can be adjusted to ensure that the temperature of the forgings after cleaning is small, which is conducive to subsequent forging. |

|

1,The whole machine adopts stainless steel plastic spraying, black

6,After removing the oxide scale, the metallographic structure of the product has no change

| Name | Model | Dimension(mm) | Equipment power | Flow |

|

Small Regular Descaling Machine |

DMR-80-20 |

1300*1500*1360 |

4.3KW |

4m³/h |

|

Suitable for bar diameter(mm) |

Width and height after blank making(mm) |

Number of nozzles |

Material |

Chain specification |

|

15-80 |

80*80 |

14 |

201 spray |

12A |