Item NO.:

DMS-150-30-CPayment:

50%DOWN PAYMENT,50% BEFORE SHIPPINGProduct Origin:

CHINAColor:

WHITEGoods stock:

50Product weight:

900 kgShipping Port:

SHANGHAILead Time:

2 MONTHS

Non-standard Custom 15.75KW Double Pump Descaling Machine

Why to remove the oxide scale on the forging surface?

In the forging production process, the metal blank need to be heated to high temperature, steel react with oxygen on the billet surface, which will generate a layer of scale.

If the oxide scale on the forging surface is not removed before forging production , the following hazards will occur:

1.The decline of product surface quality directly affects the qualification rate of forgings.

2.The flash allowance of forgings increases, resulting in waste of raw materials and inc。reasing the time of later machining.

3.The oxide scale on the forging surface will accelerate the loss of the die and affect the life of the forging die.The hot billet and round bar forging descaling machine adopts double pump design and uses the principle of oxide scale removal by high-pressure water to remove the scale of forgings in a very short time without causing the decrease of forging surface temperature. At present, it has been widely used in China's forging industry. There are many successful cases of large customers. The forging descaling machine can be customized according to the customer's on-site situation.

|

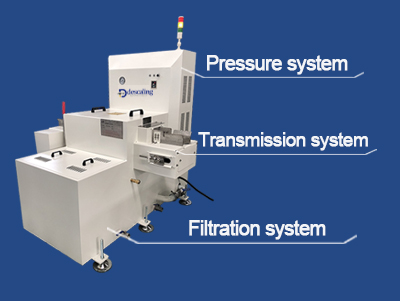

The descaling machine from Descaling technology, the main body of the equipment is composed of a pressure system, a transmission system and a filtration system. The three systems jointly use the principle of high-pressure water descaling to complete the cleaning process of the forging scale. |

|

The high-pressure water descaling system is adopted, and the high-pressure water generated by the high-pressure water pump enters the descaling nozzle and is sprayed on the surface of the forging (or intermediate billet). The oxide scale has undergone the process of being cut, rapidly cooled and contracted, peeled from the base material, and washed away from the surface of the forging, thereby removing the oxide scale.

|

|

|

The descaling machine is equipped with two water tanks. The water tank has a built-in filter screen and a net basket to form the filter system of the equipment to prevent oxide scale from entering the water pump and affect the service life of the equipment. At the same time, it is equipped with a magnetic shovel to clean the oxide scale in the water tank. |

|

The frequency conversion motor and the chain constitute the transmission system, which is responsible for transporting the forgings for the cleaning process. The transmission speed of the chain can be adjusted to ensure that the temperature of the forgings after cleaning is small, which is conducive to subsequent forging. |

|

1, The main body of the water tank is made of 304 stainless steel and painted with blue sky

2, The exit and entrance adopt integral welding with high parallelism

3, Front and back built-in baffle, less splash, easy maintenance

4, Compared with the conventional 120 type machine, the pressure is higher, up to 3.0MPa

5, Compared with the conventional 120 type machine, the cleaning range of bar material is larger

6,The nozzle mounting seat is welded with stainless steel, which is easy to maintain

7,Comprehensive treatment of oxide skin, less lower the temperature

8,After removing the oxide scale, the metallographic structure of the product has no chang

| Name | Model | Dimension(mm) | Equipment power | Pump brand | Flow |

|

Custom 150 Double Pump Descaling Machine |

DMS-150-30-C |

1550*1600*1460 |

15.75KW |

Nanfang pump |

8m³/h |

|

Suitable for bar diameter(mm) |

Width and height after blank making(mm) |

Number of nozzles |

Material |

Transmission motor |

Chain specification |

|

20-150 |

150*150 |

20 |

304 stainless steel |

Speed control motor |

16A |