Drive Cross shaft Double Pump Descaling Machine is applicable to the oxide scale cleaning of forgings in car,for example car gears,connecting rods etc. And it can clean the scale of 20-150mm diameter round bars after heating in induction furnace,and also could clean the size under 150*150mm hot billets.

Item NO.:

DMS-150-30Payment:

50%DOWN PAYMENT,50% BEFORE SHIPPINGProduct Origin:

CHINAColor:

BLUEGoods stock:

100Product weight:

900 kgShipping Port:

SHANGHAILead Time:

1 MONTH

Drive Cross shaft Double Pump Descaling Machine

How to control the scale problem of precision forgings in hot die forging?

The oxide scale on hot forgings seriously affects the accuracy and appearance of forgings. The control methods mainly include: heating with controllable atmosphere, strictly controlling the heating temperature, selecting warm upsetting process and heating isolation film technology (such as heating coating). In addition, the method of removing oxide scale after heating from the electric induction furnace can also be adopted.

The production quantity of oxide scale depends on the steel grade, induction furnace type and heating atmosphere. Forging stock has a great influence on oxide scale. Therefore, the heating time cannot be extended arbitrarily, and the heating equipment and heating mode should be actively improved. The method of roughening the blank once can be used to remove the oxide scale on the press or hammer; Then, after each blow twice, take out the forging and blow off the oxide scale. This helps to reduce the influence of oxide scale on die forging blank. In addition, hydraulic scale removal, scraping, wire brushing and the use of blank making and pre forging groove to break the scale can reduce the wear of the die.

At present, China's forging industry has taken the descaling process as standard in the forging production line. The descaling cleaning machine has been widely used in the Chinese market for 8 years and has received good feedback.

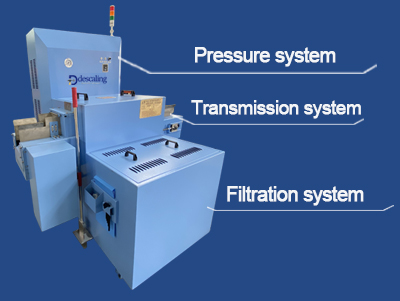

The descaling machine from Descaling technology, the main body of the equipment is composed of a pressure system, a transmission system and a filtration system. The three systems jointly use the principle of high-pressure water descaling to complete the cleaning process of the forging scale.

The high-pressure water descaling system is adopted, and the high-pressure water generated by the high-pressure water pump enters the descaling nozzle and is sprayed on the surface of the forging (or intermediate billet). The oxide scale has undergone the process of being cut, rapidly cooled and contracted, peeled from the base material, and washed away from the surface of the forging, thereby removing the oxide scale.

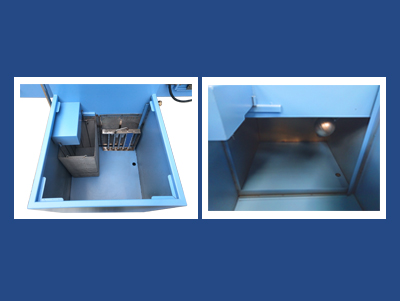

The descaling machine is equipped with two water tanks. The water tank has a built-in filter screen and a net basket to form the filter system of the equipment to prevent oxide scale from entering the water pump and affect the service life of the equipment. At the same time, it is equipped with a magnetic shovel to clean the oxide scale in the water tank.

The frequency conversion motor and the chain constitute the transmission system, which is responsible for transporting the forgings for the cleaning process. The transmission speed of the chain can be adjusted to ensure that the temperature of the forgings after cleaning is small, which is conducive to subsequent forging.

1,The main body of the water tank is made of 304 stainless steel and painted with blue sky

2,The exit and entrance adopt integral welding with high parallelism

3,Front and back built-in baffle, less splash, easy maintenance

4,Integral cover to protect pump motor

5,Compared with the conventional descaling machine, the flow rate is large, and it is suitable for the refractory oxide scale products

6,The nozzle mounting seat is welded with stainless steel, which is easy to maintain

7,Comprehensive treatment of oxide skin, less lower the temperature

8,After removing the oxide scale, the metallographic structure of the product has no chang

9,Integral cover to protect pump motor

| Name | Model | Dimension(mm) | Equipment power | Pump brand | Flow |

|

Large Double Pump Descaling Machine |

DMS-150-30 |

1550*1600*1460 |

15.75KW |

Nanfang pump |

8m³/h |

|

Suitable for bar diameter(mm) |

Width and height after blank making(mm) |

Number of nozzles |

Material |

Transmission motor |

Chain specification |

|

20-150 |

150*150 |

20 |

304 stainless steel |

Speed control motor |

16A |

1. What kind of forging pieces is descaling machine suitable for?