200KG Extrahigh Pressure Ship Forgings Descaling Machine has filled the blank of domestic forging oxide scale removal equipment, and it can clean the scale of 50-200mm diameter round bars after heating in induction furnace.

Item NO.:

DME-200-200Payment:

50%DOWN PAYMENT,50% BEFORE SHIPPINGProduct Origin:

CHINAColor:

STAINLESSGoods stock:

50Product weight:

1500 kgShipping Port:

SHANGHAILead Time:

3 MONTHS

200KG Extrahigh Pressure Ship Forgings Descaling Machine

Equipment principle:

In the forging descaling machine system, the high-pressure water produced by the high-pressure water pump enters the nozzle of the descaling cleaner. Under the action of the nozzle, the high pressure water forms a fan-shaped water beam with great impact force, which is sprayed onto the surface of the hot billet forgings (or intermediate billet). Under the action of the high pressure fan-shaped water jet beam, the oxide scale has undergone the process of cutting, quenching and shrinking, stripping from the base metal and washing it away from the surface of the billet (or intermediate billet), so as to clean the oxide scale.

When the high pressure water is hit to the hot billet surface through the nozzle, the following changes will occur:

1.The fan-shaped formed by water flow is like a sharp blade, which cuts the dense iron sheet to form cracks. It can be seen that the thin fan-shaped has more striking power;

2.High pressure water evaporates rapidly through cracks, which results in similar blasting effect, which will peel off oxide sheet from base metal;

3. When the scale is impacted by water, it shrinks when it is cold and produces transverse shear force, which makes the scale peels off from the base metal;

4. The water jet with rake angle scours the loose iron sheet.

|

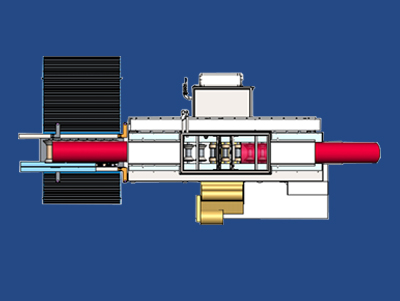

The descaling machine from Descaling technology, the main body of the equipment is composed of a pressure system, a transmission system and a filtration system. The three systems jointly use the principle of high-pressure water descaling to complete the cleaning process of the forging scale. |

|

The frequency conversion motor and the chain constitute the transmission system, which is responsible for transporting the forgings for the cleaning process. The transmission speed of the chain can be adjusted to ensure that the temperature of the forgings after cleaning is small, which is conducive to subsequent forging.

|

|

|

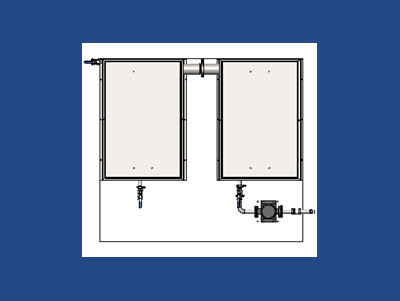

The descaling machine is equipped with two water tanks. The water tank has a built-in filter screen and a net basket to form the filter system of the equipment to prevent oxide scale from entering the water pump and affect the service life of the equipment. At the same time, it is equipped with a magnetic shovel to clean the oxide scale in the water tank. |

| The high-pressure water descaling system is adopted, and the high-pressure water generated by the high-pressure water pump enters the descaling nozzle and is sprayed on the surface of the forging (or intermediate billet). The oxide scale has undergone the process of being cut, rapidly cooled and contracted, peeled from the base material, and washed away from the surface of the forging, thereby removing the oxide scale. |

|

1, The main body of the water tank is made of 304 stainless steel and painted with blue sky

2, The exit and entrance adopt integral welding with high parallelism

3, Front and back built-in baffle, less splash, easy maintenance

4,The nozzle mounting seat is welded with stainless steel, which is easy to maintain

5,Comprehensive treatment of oxide skin, less lower the temperature

6,After removing the oxide scale, the metallographic structure of the product has no chang

7,Equipped with workstation, automatically remove oxide scale, reduce maintenance

8,Equipped with cooling tower, multiple filtration

| Name | Model | Workstation size(mm) | Equipment size | Total power of equipment | Brand of high pressure pump | High pressure water pump flow |

|

200KG Extrahigh pressure descaling machine |

DME-200-200 |

3000*2000*2000 |

Refer to the model |

40KW |

ITALY |

60L/min |

|

Motor brand |

Motor power |

Cooling tower brand |

Cooling tower power |

Electric brand |

Brand of multistage magnetic separator |

Power of multi-stage magnetic separator |

|

SIEMENS |

30KW |

LITAI |

2KW |

Schneider |

LITAI |

200W |

|

Suitable for bar diameter(mm) |

Maximum width after blank making |

Number of nozzles |

Material |

Transmission motor |

Inverter brand |

Transmission mode |

|

50-200 |

300 |

6 |

304 stainless |

Option |

SIEMENS |

Option |