100KG Extrahigh Pressure Shipbuilding Steel Forgings Descaling Machine has filled the blank of Chinese forging oxide scale removal equipment.After the impact of high-pressure water flow, the scattered oxide scale can be washed out to achieve the purpose of completely removing the oxide scale. It is suitable for cleaning large forgings, such as spaceflight forgings, ship forgings and military forgings.

Item NO.:

DME-100-100Payment:

50%DOWN PAYMENT,50% BEFORE SHIPPINGProduct Origin:

CHINAColor:

STAINLESSGoods stock:

50Product weight:

1100 kgShipping Port:

SHANGHAILead Time:

3 MONTHS

100KG Extrahigh Pressure Shipbuilding Steel Forgings Descaling Machine

During the hot forging process of large forgings, the oxide scale on the surface also needs to be cleaned. Due to the large blank size, it is more difficult to clean. The ultra-high pressure oxide scale cleaning machine developed by Nanjing Descaling Technology can customize the roller transmission and high-pressure system according to the size of large-size forging, filling the gap of oxide scale removal equipment for large forgings.

Equipment features:

1.The cleaning speed can be easily adjusted according to the product size, and there is almost no loss of temperature before and after cleaning, the metallographic structure does not change, and the forge production process is not affected;

2. National utility and appearance patents;

3. Pure stainless steel 304 material, water tank wall thickness of 5mm, anti-corrosion and durable;

4. The imported motor, pump body and sealing ring are used for durability, and the accumulator is used to solve the problems of high pressure resistance, safety and cleaning;

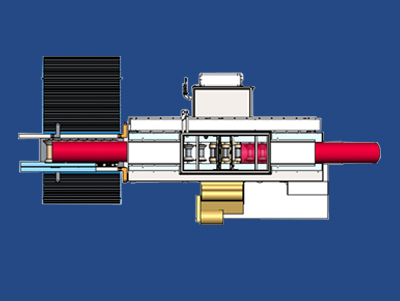

5. Motor roller transmission mechanism is adopted to ensure 360 ° cleaning without dead angle and no sticking point;

6. Four filtration systems are used to effectively collect the small piece of oxide scale, and another system is used to collect and automatically remove the oxide scale;

7. Adopting frequency conversion technology, energy saving and environmental protection;

8. In order to ensure the safety of motor and water pump, the water level alarm device is designed, which can set the water level limit arbitrarily, so as to remind us of equipment failure or maintenance;

9.High pressure rotary nozzleis used, and the pressure resistance is over 300kg, which increases by 20% on the basis of ordinary pressure resistant nozzle, and improves the cleaning effect;

10. The following functions can be customized: forging cleaning, no material stop, discharge function, switching function, touch screen display function, chip removal function, sleep function, etc.

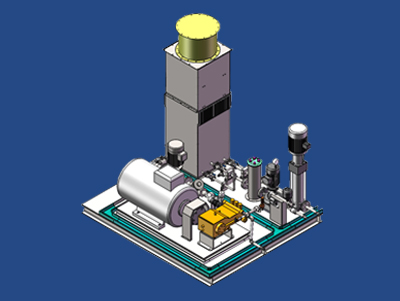

The descaling machine from Descaling technology, the main body of the equipment is composed of a pressure system, a transmission system and a filtration system. The three systems jointly use the principle of high-pressure water descaling to complete the cleaning process of the forging scale.

The frequency conversion motor and the chain constitute the transmission system, which is responsible for transporting the forgings for the cleaning process. The transmission speed of the chain can be adjusted to ensure that the temperature of the forgings after cleaning is small, which is conducive to subsequent forging.

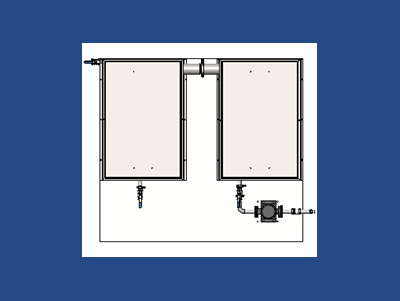

The descaling machine is equipped with two water tanks. The water tank has a built-in filter screen and a net basket to form the filter system of the equipment to prevent oxide scale from entering the water pump and affect the service life of the equipment. At the same time, it is equipped with a magnetic shovel to clean the oxide scale in the water tank.

1, The main body of the water tank is made of 304 stainless steel and painted with blue sky

2, The exit and entrance adopt integral welding with high parallelism

3, Front and back built-in baffle, less splash, easy maintenance

4,The nozzle mounting seat is welded with stainless steel, which is easy to maintain

5,Comprehensive treatment of oxide skin, less lower the temperature

6,After removing the oxide scale, the metallographic structure of the product has no chang

7,Equipped with workstation, automatically remove oxide scale, reduce maintenance

8,Equipped with cooling tower, multiple filtration

|

Name |

Model | Workstation size(mm) | Equipment size | Total power of equipment | Brand of high pressure pump | High pressure water pump flow |

|

100KG Extrahigh pressure descaling machine |

DME-100-100 |

3000*2000*2000 |

Refer to the model |

40KW |

ITALY |

60L/min |

|

Motor brand |

Motor power |

Cooling tower brand |

Cooling tower power |

Electric brand |

Brand of multistage magnetic separator |

Power of multi-stage magnetic separator |

|

SIEMENS |

30KW |

LITAI |

2KW |

Schneider |

LITAI |

200W |

|

Suitable for bar diameter(mm) |

Maximum width after blank making |

Number of nozzles |

Material |

Transmission motor |

Inverter brand |

Transmission mode |

|

50-200 |

300 |

6 |

304 stainless |

Option |

SIEMENS |

Option |

1. What kind of forging pieces is descaling machine suitable for?