Non-standard Custom-made Large Double Pump Descaling Machine is applicable to the oxide scale cleaning of all kinds of forgings, and it can clean the scale of 70-130mm diameter round bars after heating in induction furnace, and also could clean the size under 130*130mm heated blanks. It is especially suitable for cleaning large forgings. The equipment can be equipped with a hot die forging production line as the surface treatment process of hot forgings. The recommended method is to remove the oxide skin after heating in the induction furnace, and then carry out subsequent forging hammer or press processing, which can maximize the surface quality of forgings.

Item NO.:

DMC-150-30Payment:

50% DOWNPAYMENT,50% BEFORE SHIPPINGProduct Origin:

CHINAColor:

STAINLESSGoods stock:

50Product weight:

1000 kgShipping Port:

SHANGHAILead Time:

2 MONTHS

Non-standard Custom Fastener Standards Double Pump Descaling Machine

Non-standard Custom Fastener Standards Double Pump Descaling Machine can clean all kinds of large fasteners and forgings, such as screw and nut fasteners for containers and all kinds of container accessories, large marine fasteners and all kinds of marine accessories, fasteners for precision machinery and other high-strength fasteners. At present, it has been widely used in the forging industry in China, serving hundreds of fastener manufacturers, and successfully helping forging manufacturers improve the hot die forging process. The high-strength fasteners after oxide skin cleaning have smoother surface, improved quality, more market competitiveness, effectively improve the service life of molds and fundamentally save costs.

The following double pump forging scale cleaning machines are designed with two pumps, which can effectively increase the water pressure and are suitable for the scale cleaning process of large forgings. Compared with the conventional scale cleaning machine, the oxide forge scale removal machine is added, which can better filter the scale, increase the durability of the equipment, and facilitate the on-site maintenance of the forging plant and the improvement of the environment. If necessary, we will provide solutions, Please contact Nanjing Descaling Technology. We will provide customized services according to your forging conditions to achieve the best oxide scale cleaning effect.

|

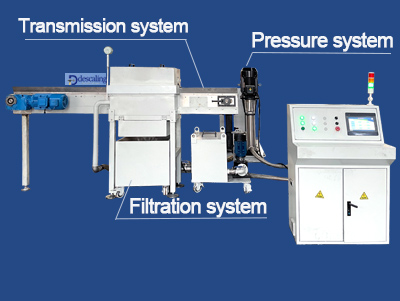

The descaling machine from Descaling technology, the main body of the equipment is composed of a pressure system, a transmission system and a filtration system. The three systems jointly use the principle of high-pressure water descaling to complete the cleaning process of the forging scale.

|

| The high-pressure water descaling system is adopted, and the high-pressure water generated by the high-pressure water pump enters the descaling nozzle and is sprayed on the surface of the forging (or intermediate billet). The oxide scale has undergone the process of being cut, rapidly cooled and contracted, peeled from the base material, and washed away from the surface of the forging, thereby removing the oxide scale. |

|

|

The frequency conversion motor and the chain constitute the transmission system, which is responsible for transporting the forgings for the cleaning process. The transmission speed of the chain can be adjusted to ensure that the temperature of the forgings after cleaning is small, which is conducive to subsequent forging. |

| The descaling machine is equipped with two water tanks. The water tank has a built-in filter screen and a net basket to form the filter system of the equipment to prevent oxide scale from entering the water pump and affect the service life of the equipment. At the same time, it is equipped with a magnetic shovel to clean the oxide scale in the water tank. |

|

1, The main body of the water tank is made of 304 stainless steel and painted with blue sky

2, The exit and entrance adopt integral welding with high parallelism

3, Front and back built-in baffle, less splash, easy maintenance

4,The nozzle mounting seat is welded with stainless steel, which is easy to maintain

5,Comprehensive treatment of oxide skin, less lower the temperature

6,After removing the oxide scale, the metallographic structure of the product has no chang

| Name | Model | Dimension(mm) | Equipment power | Pump brand | Flow |

|

Custom Double Pump Descaling Machine |

DMC-150-30 |

/ |

25.43KW |

Nanfang pump |

12m³/h |

|

Suitable for bar diameter(mm) |

Width and height after blank making(mm) |

Number of nozzles |

Material |

Transmission motor |

Chain specification |

| 70-130 |

130*130 |

28 |

304 stainless steel |

Speed control motor |

16A |